Festo Develops New Solutions for Automating EV Battery Manufacturing

October 15, 2024

Festo has recently created a new solution for high throughput dry-room electrode assembly of EV batteries.

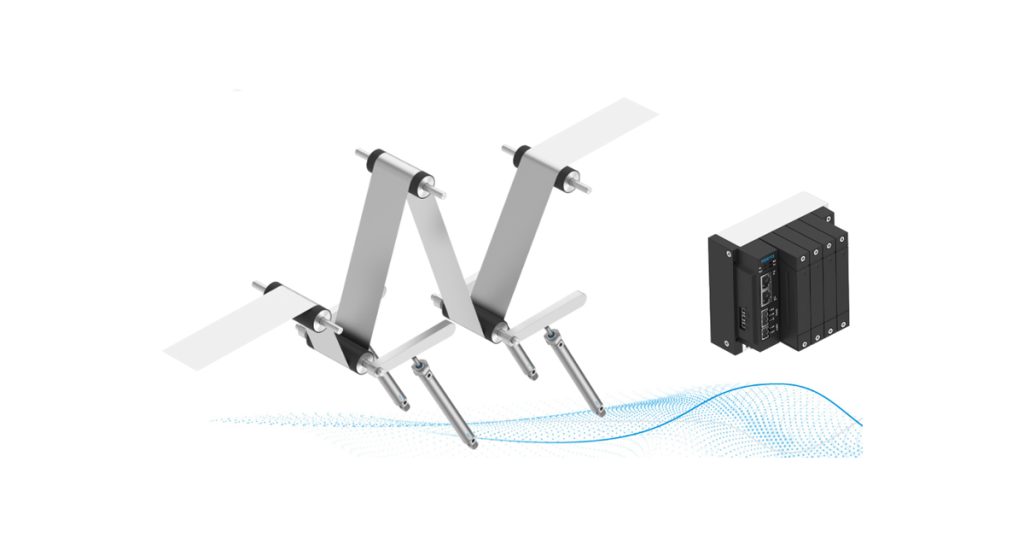

In 2022, the Festo electric mobility initiative demonstrated an automated degassing cell. In 2023, the company developed an automated chemical processing solution for recycling the valuable materials incorporated within EV batteries. Now, in 2024, Festo focuses on dry-room electrode production. A new display of the solution simulates the unrolling, cutting, aligning, and layering of anodes and cathodes.

The first high-precision proportional valve terminal on the market – the new Festo VTEP – maintains roll tension, which is critical to the quality of EV batteries, and does so at a significant cost saving compared to electric automation. VTEP is the latest Controlled Pneumatics solution from Festo. Controlled Pneumatics is the next stage in the evolution of pneumatic solutions for the 21st century. Controlled Pneumatics solutions combine high-speed, long-life, and energy-efficient piezo-electric valve cartridges with sensors and control algorithms into a single smart unit.

With the VTEP, users set performance parameters per valve channel and the proportional pressure valves provide closed-loop control to those presets. Valves deliver highly dynamic response and precise pressure control to achieve “target reached” status for each channel, which equates to the motion complete function in electric drive technology. Sustaining the target setting makes the VTEP terminal ideal for maintaining roll tension in automated dry room electrode production.

The solution highlights the performance advantages linked to huge bandwidth – 200-megabyte rate – and exceedingly low cycle time – under 100 milliseconds – of the new Festo Automation Platform (AP) I/O. The AP’s CPX-AP-A remote I/O and CPX-AP-I decentralized I/O communicate at backplane speed. This I/O architecture is compatible with EtherNET/IP, PROFINET, EtherCAT, Modbus, and IO-Link by applying a protocol-specific AP bus module. This is a plus for OEMs supplying multiple control systems on serial machines as the bus module changes, while the I/O stays the same.

The Festo components for dry room applications are copper and zinc free, which adhere to best industry practice. Festo offers copper and zinc free options in dozens of product families, including valve manifolds, actuators, air preparation systems, and accessories. Festo copper and zinc free product variants feature a “F1A” designation in their model numbers.

Closing the skills gap in EV and semiconductor manufacturing

Closing the skills gap – the disparity between skills needed by industry and the number of workers with those skills – is vital to the health of EV and semiconductor manufacturing due to the number of new plants and revitalization projects coming online. Festo Didactic, the learning arm of Festo, now offers Electromobility Training online through the Festo Learning Experience portal, on-site customized training, and expertise in establishing and maintaining apprenticeship programs.

Festo transformed itself during the past twenty years from a pneumatic component supplier to the top mechatronics company in the world – pneumatic and electric automation with pneumatic and electric systems applied singly or in combination under a unified state-of-the-art architecture. In addition to mechatronic solutions, Festo offers original equipment manufacturers (OEMs) and end users productivity tools and training for shortening time to market and maximizing uptime.